Welcome to visit us!

Dada invested to expand its production line and modernize their standard workshops in order to optimize the production of high quality circuit breakers. The stamping workshop, spot welding workshop, riveting workshop, injection molding workshop, and assembly workshop are all configured to maximize the production output of outstanding circuit breakers. The factory covers an area greater than 50,000 square meters and supplies an annual output of 400,000 MCCB and 2,000,000 MCB.

Process workshops

Stamping workshop

Welding workshop

Baklite workshop

Riveting workshop

Injection workshop

Spot welding workshop

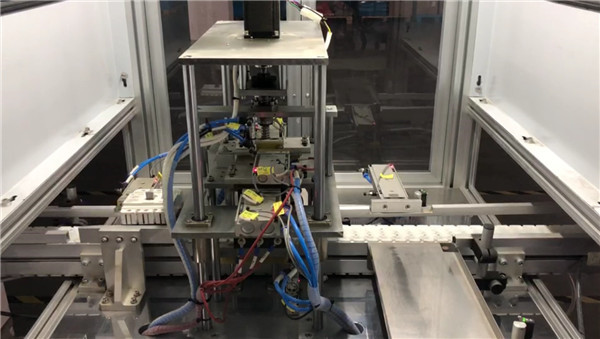

Assembly workshops

Assembly line 1

Assembly line 4

Assembly line 2

Assembly line 5

Assembly line 3

Assembly line 6

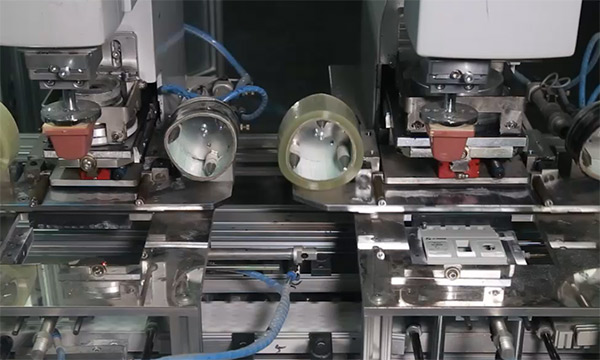

Machines

Automatic printing machine

Automatic welding machine

Automatic tapping machine

Automatic printing machine

Automatic profile projector

Automatic endurance testing machine

Automatic printing machine

Automatic deburring machine

Electromagnetic compatilbility test machine

Detection process

1. Purchased parts / cooperation parts detection, qualified use, unqualified returns

2. Purchase raw materials, qualified warehouse, unqualified returns

3.The raw material is processed, and the test is carried out by punching / tapping / riveting / pressure injection, then the surface treatment is carried out after the inspection is qualified

4. Before the parts are assembled, they are tested for pressure resistance and high-temperature resistance, rework if unqualified

5. Before shipment, the factory inspection is carried out, and the performance is tested.

Testing equipment

Magnetic testing

Tripping limit testing

Overload testing

parts inspection

Magnetic and Overload testing